Soap Packing Machine Manufacturer

- Shreem Engineers

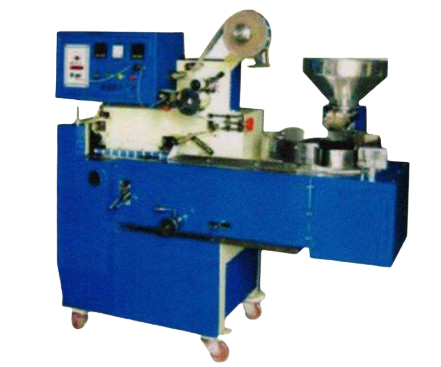

- Soap Packing Machine

Soap Packing Machine Manufacturer

The Soap Packing Machine Manufacturer is a high-performance packaging solution designed to wrap solid items like biscuits, chocolates, soaps, chikki, and ice candy with precision and efficiency. It is equipped with Delta A2 Series servo systems at the cutter sealer, die roller, machine conveyor, and feeding conveyor to ensure smooth operation, accurate positioning, and reduced backlash.

The Soap Packing Machine features a Panasonic I-Mark sensor for fast and reliable mark detection, a Delta PLC with digital inputs and outputs for seamless control, and a temperature control system for the die roller and sealer, adjustable directly via the HMI display. Designed for both manual and automatic modes, the machine offers operator-friendly controls and safety features such as alerts and alarms for any system errors.

Looking to speed up your soap production? Take a peek at the Soap Packing Machine and see how simple it can be.

| Component | Description |

|---|---|

| Application | To wrap any kind of solid commodities such as Biscuits, Soaps, Chocolates, Ice Candy, Chikki, Bearing, etc. |

| Brand | Shreem Engineers |

| Filling Range | Depends on Specific Products |

| Packing Speed | 70 to 130 Pouches/Minutes |

| Type of Sealing | Centre Sealing |

| Pouch Dim. | L: 40–300 mm, Film W: 20–125 mm, H: 5–56 mm |

| Pouch Film Material | All Types Of Heat Sealable Laminates |

| Power Req. | 2 H.P, 200–50V/50Hz Heater: 2 × 125 W + 4 × 125 W |

| Machine Weight | 450 kgs. (approx) |

| Filling Material Contact Parts | Stainless Steel AISI 304 Grade |

| Dosing System | Automatic & Manual Feeding |

| Automation Grade | Automatic |

| Voltage | 220 Single Phase (or) 440 Three Phase |

| Machine Size | 3920 × 670 × 1320 |

| Power Consumption | 2.4 kW |

| Frequency | 50–60 Hz |

| Product Height | Max. 50 mm |

Why Choose Our Soap Packing Machine?

Let’s be honest, soap packing needs to be clean, consistent, and fast. A small issue in sealing or wrapping can spoil the look of the product. Our Soap Packing Machine is designed keeping real production needs in mind, not just specifications on paper.

Reliable After-Sales Support

Once the machine is installed, our job doesn’t end there. We help with setup, operator training, and support whenever something needs attention. You won’t be left alone after buying the machine.

Easy Availability of Spare Parts

Production should not stop because of one small part. We keep commonly required spares available so your Soap Packing Machine can get back to work quickly.

Simple Operation and Maintenance

The machine is easy to understand and operate. Daily cleaning and basic maintenance can be handled by trained staff without calling technicians for every small issue.

Clean and Professional Packaging

This machine ensures neat wrapping and strong sealing. Your soap bars come out well-packed, protected, and shelf-ready every time.

Works with Different Soap Sizes

Regardless of the size of the soap bars you are packing, small or large, the Soap Packing Machine can be modified according to the measurements and the style of your product packaging.

Cost-Efficient for Long-Term Use

It provides consistent performance at a low cost, which makes it suitable for both small manufacturers and developing brands.

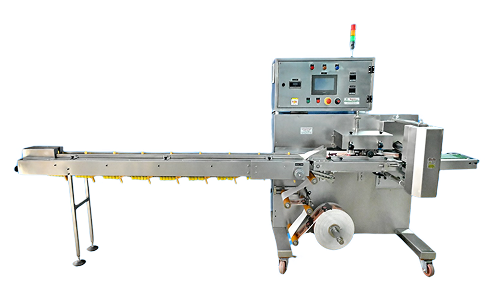

This soap packing machine is designed for efficient and secure wrapping of different soap sizes. For high-speed pillow-type wrapping, you can also explore our Horizontal Flow Wrapping Machine, and for similar wrapping applications in the food industry, check our Chocolate Packing Machine.

Explore real machine working videos on our Shreem Engineers YouTube Channel.

Features of Soap Packing Machine

- The Machine adopts PLC & HMI programming software, ensuring easy operation, self-failure diagnosis, and clear failure display.

- High sensitivity photocell tracing with input cutting & sealing position digitally for extra accuracy.

- PID temperature control independently, making the Soap Packing Machine more suitable for packing different materials.

- Touch screen support for convenient operations.

- Simple driving system with reliable working and easy maintenance.

- All control is realized through software, enabling function adjustment and technical upgrades.

Applications

Biscuits

Soaps

Chocolates

Ice Candy

Chikki

Frequently Asked Questions (FAQs)

- What kinds of soaps can this Soap Packing Machine pack?

The Soap Packing Machine is perfect for the solid soap bars of all shapes and sizes. It will be a very good option for toilet soaps, beauty soaps, and similar solid products used in the daily consumer market as well.

- Is the machine good for continuous production?

Absolutely, the machine is made to perform regularly and continuously. It can manage the daily production very well, thus it is perfect for factories with a steady output requirement.

- Can the Soap Packing Machine take care of packing?

The process is very simple and hassle-free. Once the basic instruction is given, the operators can go ahead and carry out daily functions like starting, stopping, and monitoring the packing process without any trouble.

- What kind of packing material is allowed?

The machine is compatible with a wide range of heat-sealable wrapping films. The selection of the material will be based on the finish you want and the degree of protection the soap needs.

- What is the maintenance schedule of the machine?

The machine needs only basic routine maintenance. Regular cleaning, plus simple checks, are the preventive measures taken against unexpected downtime and help keep the Soap Packing Machine operating effortlessly.

- Is the support provided after the installation?

Certainly, we offer full support after the installation. This includes operator support, technical help, and spare parts availability whenever needed.

Contact Us

Get in Touch With Shreem Engineers

Whether you need details about our packaging machines, including the Ice Candy Packing Machine, or require assistance with your existing equipment, our team is just a message away. Reach out via phone, email, or the contact form below — and we’ll get back to you as soon as possible.